Tig e Mig Welding

Welding is a special process performed according to pre-established procedures, guarantees a quite complete continuity of the mechanical and physical characteristics in the material of the joined parts. The complete control over the welding process, from the chemical characteristics of the material to the final radiographic control, allows to completely eliminate human error, despite the fact that man himself is the key to this process. Qualified employees for TIG welding according to AWS D 17.1: 2010, UNI EN 9606-1: 2013 ASME-IX and the welding coordinator WELDING INSPECTOR level-2 (CSWIP 3.1 level 2 of TWI) according to BS EN ISO 17637: 2011 guarantee the implementation of the protocol in compliance with the regulations in force.

Aeronautical constructions

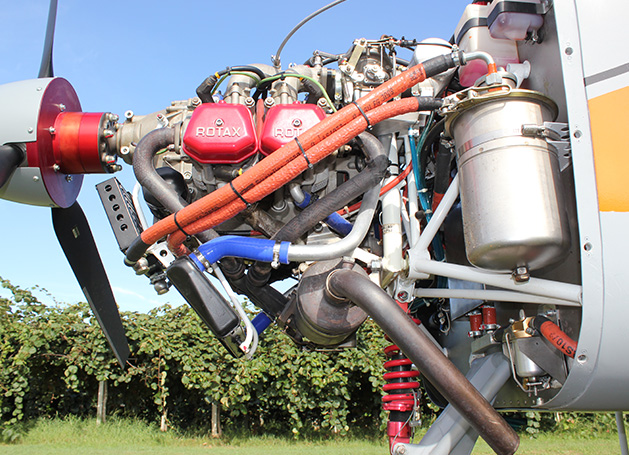

The constructive solutions of TIG welded lattice structures, engine castles, wings with independent spars and braced wings support all the elements deriving from the design and related industrialization. We carry out construction, overhaul, maintenance and runway of AG - VLA - UL - VDS aircraft.

Aeronautical Assemblies

Starting from the understanding of the technical drawing, the assembly cycle and constant control give life to a highly precise and complex technical operation, aimed at the construction and / or assembly of aeronautical structures.

Radiographic checks

The purpose of the X-ray checks is to issue an acceptance / rejection judgment of a material or component with full guarantee and functionality for which the object itself was built. The final part of the welding process is one of the most important: the radiographic control is internal and certified thanks to the presence in the company of qualified employees according to EN 4179 / NAS 410 UNI EN ISO 9712: 201 to guarantee constant control of the production processes and the improvement of the same. Controls can also be made on specific mesaurements up to 1m x 2m in size.

Other Services

Mechanical processing based on drawings and samples, Sheet metal work and pipe bending, Construction of cross-linked structures with chromium molybdenum steel pipes (25CrMo4 / USA 4130), made with TIG welding, Pressurization of cross-linked structures with chromium molybdenum steel pipes, with inert gas and control by means of a pressure loss detector for any breakages, Molding of aeronautical aluminum sheets, Construction of shapes and tools for contouring and construction of spindles for molding, Construction of stairways for aeronautical assemblies, Construction of wooden supports for packaging of aeronautical parts, Construction of molds for forming composite materials, Carpentry for construction of frames and various structures of aero characternautico, Centro servizi e manutenzione ordinaria motori Rotax & Limbach.